Industry

State-of-the-art technologies to resolve the water cycle in industry

The problem of water in industry

Gefico has consolidated its position as a clear leader in the industrial sector, offering solutions to the common problem of water treatment. First of all, many industrial processes need to have a supply of technical water. Secondly, industries that work with water frequently need to control the quantity and quality of their discharges, in order to comply with the regulations in force, thus avoiding environmental problems.

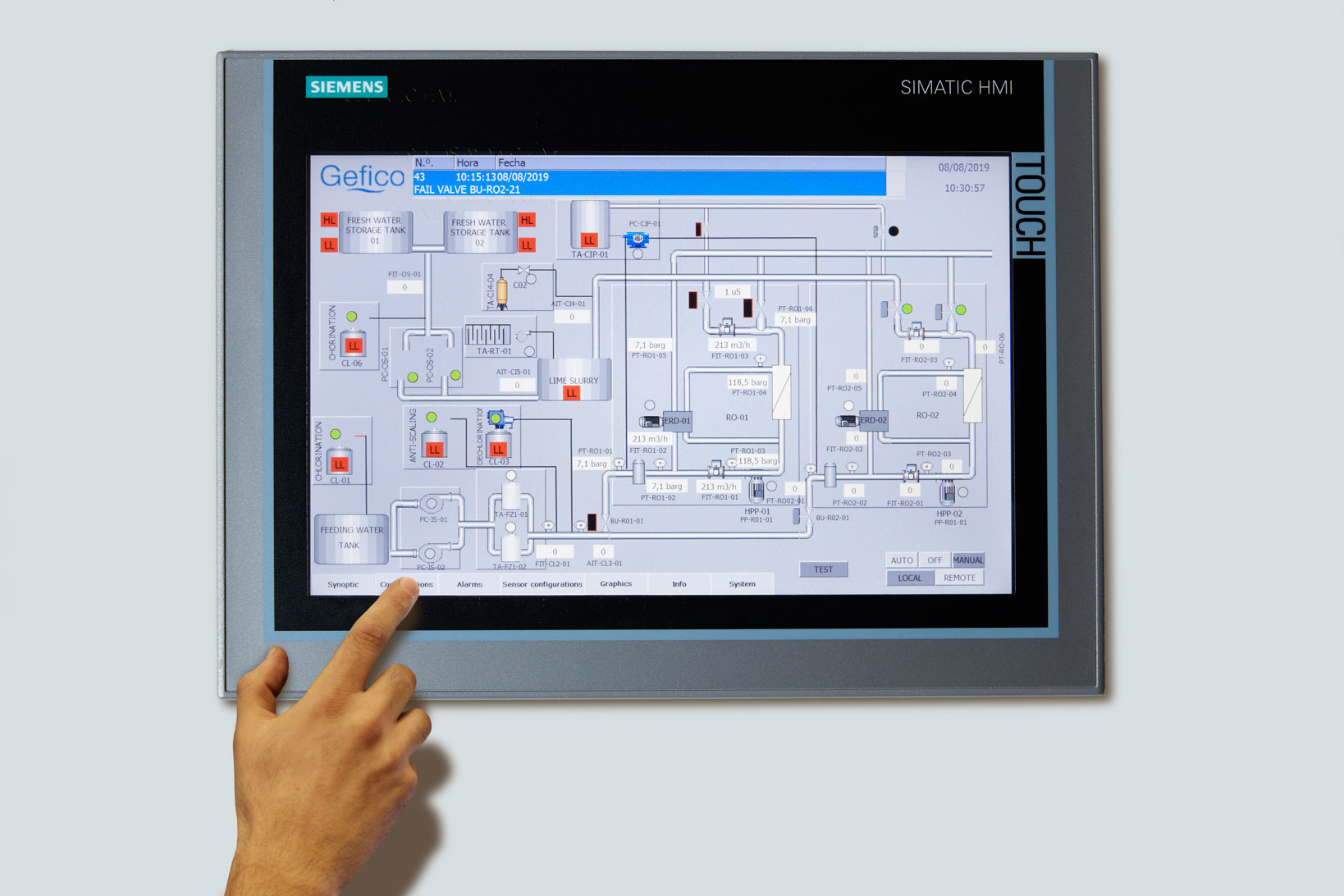

Automated solutions and with remote control

Gefico units can be designed fully or partially automated, for their operational control and monitoring, including monitoring, analysing and taking action on various parameters that influence production. The installation can be controlled locally or via a remote TCP/IP system, which means significant cost savings and improved plant quality and safety.

At Gefico we resolve situations like this using the different technologies in which we are proficient, providing solutions of great added value to the productive cycles of our customers.

Download our catalogue for the Industry and Land sector:

“On a Friday afternoon I requested a service engineer for Monday, and on Monday he was there. The cooperation I can find in Gefico is very hard to find in any other company”

Annamaria Zangrilli – CEO Marine EQ (Italy)

Solutions

Thermal evaporation

Vapor Compression Evaporation

Reverse Osmosis

Industrial Misting

Other Solutions

Thermal evaporation for industry

Gefico thermal evaporators for industry make it possible to exploit any source of waste heat (hot water, steam, thermal oil). By reducing their internal pressure, these units are able to evaporate water at a temperature well below its boiling point of 100C.

Obtaining technical water

By subsequently condensing this steam, distilled water of extraordinary purity and quality is obtained. The low temperatures prevent chemical changes in the products we are evaporating, and with this:

✔ The generation of volatile substances that could otherwise contaminate the distillate produced

✔ The appearance of incrustations on heat exchange surfaces

Main Applications:

✔ Cogeneration (CHP) plants

✔ Industrial plants that call for the concentration of waste with a high water content

✔ Industrial plants that require waste water treatment

✔ Industrial applications and processes that require technical water

Benefits:

✔ Taking advantage of the existing residual thermal energy

✔ Use of multiple thermal sources: hot water, steam, thermal oil,…

✔ Increasing the energy efficiency of the facility

✔ Reduction of the environmental impact

✔ Compliance of discharges with regulations

Vapor compression evaporation for industry

Vapor compression evaporation is a distillation technology that uses the heat of the steam generated in the process itself to continue to evaporate the incoming fluid, recirculating and feeding back into the cycle. Therefore, with this technology we can perform a distillation process without the need for an external thermal energy supply.

Benefits:

✔ Very low electricity consumption

✔ No thermal energy input is required from an external source

✔ Much more efficient distillation technology

✔ Ergonomic and user-friendly design

✔ Easy maintenance & long operating life (over 25 years).

✔ Simple and compact installation

Reverse osmosis for Industry

Reverse osmosis is a technology where seawater is pressurised through a semi-permeable membrane that only allows fresh water to flow through it. The salts and other contaminants are eliminated with the flow of brine.

A solution with countless benefits:

✔ Versatility: treatment of any type of water, either for human consumption, or for waste reduction in a pre-evaporation phase.

✔ Modular configuration: including all the components necessary for proper operation installed in a shared frame.

✔ Adaptability: manufacturing designed to meet the customer’s needs.

✔ Environmentally responsible solution: facilitates compliance with international and local directives.

Industrial Misting

Industrial misting consists of a microspraying process, which allows, among other applications, moisture levels and suspended solids to be monitored in different industrial applications. It has the following features:

Characteristics:

✔ Self-lubricating high-pressure pumps, so they do not require the use of oils.

✔ The use of special high pressure mist nozzles significantly cuts evaporation times.

✔ Compact equipment, with minimal maintenance and easy to operate.

✔ The system has a filter at the water inlet that removes impurities, to protect the pump and nozzles.

✔ Suitable for new constructions and retrofits.

Main Applications:

✔ Moisture control in industrial dryers.

✔ Cleaning and lubrication of cutting machines.

✔ Capture of suspended solids in the air.

✔ Risk reduction in ATEX zones.

✔ Firefighting systems, with no risk of damage caused by water.

✔ Systems for disinfecting and cleaning objects and people.

Other solutions for industry

✔ Dosing systems (chlorination, CIP, descaling, etc.)

✔ Sterilisation units (UV lamps, ozone generators, etc.)

✔ Ultrafiltration

References

Canning Industry

Challenge: supply of drinking water for use in an industrial canned food processing and packaging plant.

Solution: Gefico drinking water purification plant, model AQE-30D.

Aquaculture

Challenge: availability of a daily flow of one hundred tonnes of drinking water used for the fish-farming process

Solution: Gefico AQE-100 reverse osmosis drinking water purification plant

Transformation of sea products

Challenge: Brackish water treatment (1,000 – 10,000 mg/l of salts)

Solution: Gefico AQE-25BW low-pressure reverse osmosis drinking water purification plant (10-20 bar)

Our Experience

Globally present since 1979